|

My OEM Seiko watch bands seem to stretch and harden over about three years, developing cracks and eventually failing.

Replacement bands (OEM Part Number: 4GDO-BA16) used to be really expensive (no change from $100 each) but now I can’t even purchase them! I don’t want to retire a perfectly serviceable and rather expensive watch, even though it has a few cosmetic case scratches. And I don’t want to fit an alternative band as this just won’t look right without the OEM stainless steel inserts. My success with the pump seals suggests that NinjaFlex will be ideal for this application, but this will be a demanding design and print job.

This page was previously posted on my NinjaFlex 3D Printing page but it is really a project in itself.

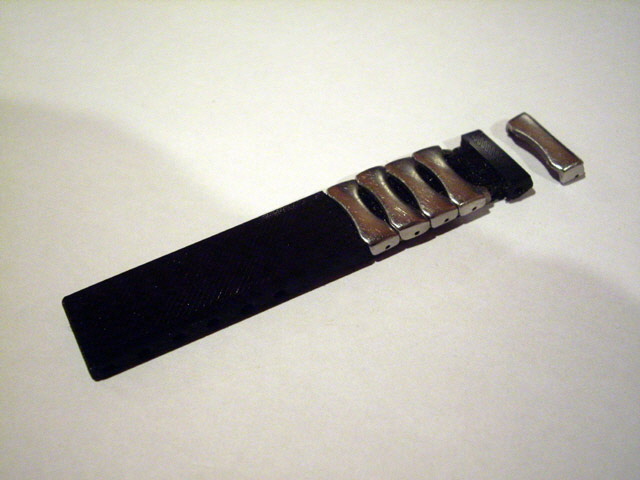

Figure 1. Seiko Watch with Worn OEM Bands

The first mission was to make a model of the OEM band. I have the original strap as a template but this will still be a challenging drawing, not helped by the fact that the original has hardened, is bent elliptical, and has worn and stretched. This will be another iterative design. First I cleaned the OEM part (watch bands get pretty dirty over time) and used scaled micro-photos for getting measurements of the part detail and hole spacing.

Figure 2. OEM Measurement

(Scale is 1 mm)

The model was sliced using Simply3D and reviewed to ensure at least two continuous outer layers to avoid a potential tear point around the numerous pin holes. I’d like to use three layers but this part has some small dimensions and tight tolerances.

The print orientation was selected to ensure that that the outer portion of the band was flat against the bed for best aesthetics for the finished band.

Figure 3. Seiko Watch Band Model

The initial model was printed using my standard NinjaFlex parameters. The print quality was great but the final print was a complete cock up. Somehow I ended up scaling the model by 1.4! Whoops, but not to worry. This will be another test piece for my vapour smoothing experiments.

The second print (with scaling back to 100%) was almost perfect. There are a few dimensional changes and some other minor model adjustments required but the part is strong, flexible, with a good surface finish; and the watch pin, catch pin and four of the five stainless steel band inserts fit perfectly. With a few minor adjustments using a soldering iron I could use this band but I’ll persist in getting the model right. Note that this relatively small part takes about an hour and a half to print, due to the slow extrusion speed and 0.23 mm layer height.

Figure 4. Second 3D Print Attempt (the first print failed due to a scaling error).

Great fit for first four inserts, minor adjustment needed for the fifth.

Figure 5. Good Clasp Pin Fit

(No adjustment needed here.)

Figure 6. Moderate Watch Pin Fit

(But I can do better than this.)

I’ve adjusted the model and, with the exception on one minor dimensional change (which I’ve already adjusted but have not yet printed), the replacement band is pretty much good to go. The band is incredibly strong - I cannot break it at full stretch (150%) between my hands. I’ve fitted it to the watch and it is comfortable and it looks great. Let’s see how it stands up to the rigors of wear for a week or two.

Figure 7. Completed NinjaFlex Band for Seiko Watch

(Foreground is NijaFlex, rear is OEM band.)

A year on and the remaining OEM watch band is on the verge of breaking. The previous NijaFlex replacement band is still completely serviceable and is showing absolutely no signs of wear and tear despite being worn 24/7. I reprinted the watch band model, fitted it, and the band looks as good as new and will probably last for years to come.

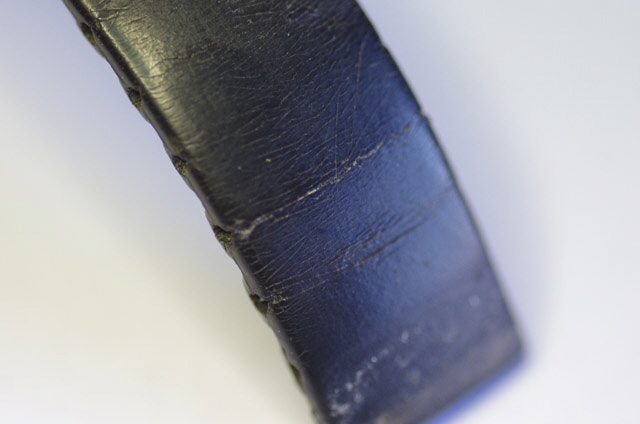

Figure 8. Remaining OEM Band on the Verge of Breaking

Figure 9. As Good as New with all-NinjaFlex Band

Job done. If you can’t find a replacement OEM band for your Seiko watch, and you’d like a replacement then please retain the old band even if it is broken and email me. The reason for retaining the OEM band is that these come in at least two widths and the length will be specific to your wrist. Maybe I can make you a replacement for little more than the cost of postage and materials.

Two years later and up until last week the bands were in perfect order, but over the last few days I have inadvertently been soaking the watch in machine cutting fluid and today I noticed that the bands were delaminating. Perhaps I should have worn gloves or taken my watch off? To cut a long story short I have simply reprinted the bands and we’re good to go again for at least another two years.

|