|

What’s that plastic membrane that forms the base of resin vat. It’s FEP or Fluorinated Ethylene Propylene.

Figure 1. FEP

Your FEP:

is a specifically engineered plastic film designed for UV light transmission, flexibility, low stretch, hardness and low surface adhesion. It manufactured to tight thickness tolerance, typically 0.150 mm.

(and a range of other engineered plastic films such as FEP2, ACP, nFEP, PFA, ...) is critical to SLA printing. It allows UV light transmission to expose the resin. Through flexing and low surface adhesion your FEP allows the exposed layer to separate during the lift cycle. It also forms the seal at the base of the resin vat.

is a consumable item with an anticipate life of approximately 300 print hours (varies between manufacturers and subject to use and abuse). Over time your FEP stretches measurably and as a consequence looses tension. It can also be subject to abrasion, scratching, indentation and puncturing.

If you listen carefully when your printer starts a lift you’ll hear a tearing or popping noise. That’s the printed model separating from the FEP. On lift the FEP initially deflects upward from the base of the vat but when the tension exceeds the peel force the model begins to separate, starting at the edge of the model or raft closest to the vat frame. Once the separation has started the peel force reduces rapidly and the model rapidly separates from the FEP and the FEP snaps back to the LCD. This is similar to overcoming static friction and the reduced force required to maintain sliding friction. The FEP tension is very important in this process. If it is too high then the separation will be a pull as opposed to a peel and the required separation force will increase. If the tension is too low then the print may not fully separate.

My very first sheet of FEP on my brand new Saturn 2 SLA printer lasted just a few short weeks. Through poor handing, inappropriate attempts to separate failed models, and poor cleaning practice I ruined it.

My second sheet lasted just over a month before I punctured it through an exposed resin particle floating in my resin vat. In this time it had stretched from the original 0.15 mm thick down to 0.13 mm.

Since my last failure I’ve used the following procedure to care for my FEP. My current FEP (although somewhat stretched) is still pristine after over a year of intermittent printing. So here’s how to look after your FEP.

After ANY print failure (including supports) filter your resin. I also like to filter my resin if the printer hasn’t been used for a few weeks before starting a new print. This is not necessary but it does ensure that the resin is free from particles and well mixed.

If a failed print has stuck to your FEP then run a clean screen. Then separate the resulting exposed film by gentle finger pressure on the bottom (LCD side) around the edges of the resin vat. The same process can be used without a clean screen for a localized print failure. Some people like to place some old supports or a failed model in a corner of the resin vat prior to running a clean screen to make a handle for film separation from above.

NEVER EVER use tools (even plastic tools) and NEVER use paper issue of towel on your FEP. Paper will abrade the FEP surface and it will rapidly turn cloudy through micro-scratching. As a consequence your next print will be even more inclined to adhere to your FEP as opposed to the build plate.

To clean your resin vat and FEP use a soft silicone squeegee and/or a 1/4” soft bristled paint brush, followed by a clean solvent rinse. If you must wipe it then use a microfibre cloth with minimal pressure.

There are a few other things that you might consider to extend the life of your FEP and ease print separation. The first is to move your models so you’re not always printing in the same spot. Some slicers will randomize your model position for you. The second is to position prints towards the ends and sides of the vat. This makes for peel, as opposed to pull FEP separation.

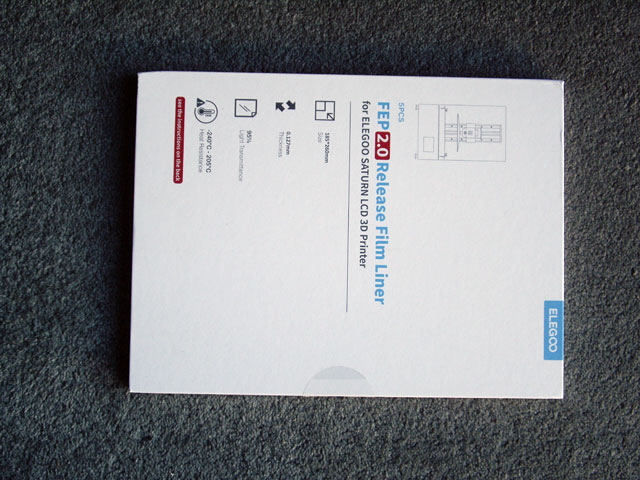

FEP is a consumable and even with careful handling it will eventually wear out through stretching. So get yourself some replacement FEP (cheaper in a a five pack) to avoid down time following a disaster or the eventual demise.

Figure 2. Five Pack of Replacement FEP

And get yourself a stainless steel resin filter, an a soft silicone squeegee, a 1/4” soft bristled paint brush; all of which will cost less than a replacement sheet of FEP.

Figure 3. You really do Need these

When it comes time to replace your FEP follow your printer manufacturer’s procedure. Make sure the frame components are clean and free from resin. For the Elegoo Saturn 2 see: https://www.elegoo.com/blogs/3d-printer-user-guide/elegoo-saturn-how-to-replace-the-fep The square foam spacer used to set the tension in Elegoo’s instructional video is 80 mm x 80 mm x 10 mm high. When replacing the numerous machine screws use finger tight to seated. Over-tightening isn’t necessary and can result in stripping of the hex head recess.

Click on Ball Screw Maintenance to read about cleaning and re-lubricating the ball screw and linear rails on your Saturn 2.

|