|

I was trying to print a prototype case. This was a 4 hour print job and the print kept failing by detaching from the bed. The bed was clean and level and made good contact with the initial print layer. Watching a further print attempt closely it became apparent that the bed was heating up to set temperature but turned off during the print, often during the first layer.

My initial thought was that I had inadvertently changed a default parameter value in the slicing software (Simplify 3D) or my preferred M2 printer interface (Pronterface). Simplify 3D allows layer control of the heated bed. To be certain I had this right I reloaded the MakerGear factory defaults for PLA and drove the printer directly from Simplify 3D. The problem had not gone away. The bed was initially heating and then cooling down during the print.

The bed was heating so the element, power supply and MOSFET switch were probably serviceable. The bed temperature was being reported so the thermal sensor was probably intact. The problem was intermittent associated with the Y axis drive which suggested a cable or a connector problem.

I checked and re-seated the fuse and the heated bed and thermal sensor connectors in the printer controller. I also checked and reseated the plugs and sockets at the heated bed end of the cable harness. Nothing was obviously defective here.

The next step was to measure the resistance of the heated bed element from the printer controller plug. This was 3.4 Ohms which was about right. This is typical of an intermittent fault - the problem that you are trying to find goes away when you start looking for it.

At this point I decided to remove the heated bed cable harness from the printer, remove the cable wrap and inspect the wiring. Nothing was obviously wrong here.

Where to next? I did an internet search on the problem and found that some folk had experienced cable breaks in the wiring between the heated bed power plug and the heated bed. I gently removed the rubberised tape from the heated bed connector to the element. The element resistance remained solid at 3.4 Ohms and the cables and plug were in excellent condition.

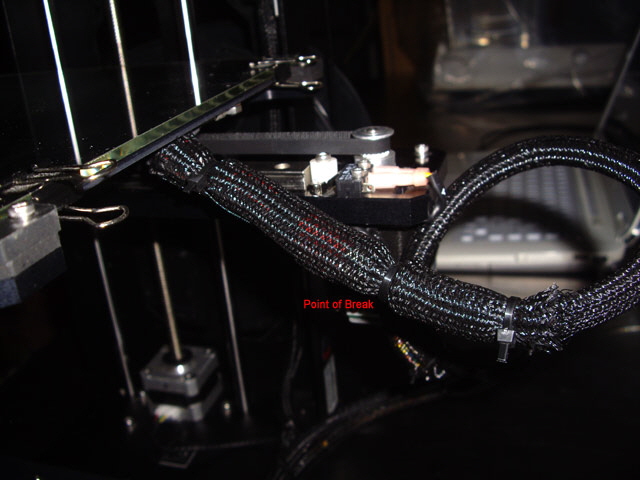

I was running out of options. Maybe there was an intermittent fault in the heated bed harness power cable under the cable sheath and/or wire insulation? The weakest point in the cable is between where the end of the sheath and the heated bed socket where the two power cables are not supported by the sheath. On further inspection and manipulation of the cable the resistance of one wire suddenly went open circuit. I pulled gently between the cable sheath and the socket and the wire stretched and broke. The inner multi-core copper conductor was discoloured indicating heating over time due to a relatively high resistance. This was almost certainly the cause of the problem.

Figure 1. Internal Conductor Break on Harness Side of HBP Socket

This is not an obvious stress point on the harness wiring because this section is supported by cable wrap and cable ties with no stress imparted by movement of the bed on the cables.

Figure 2. Heated Bed Power Cable Fault Location

I cut the cable back to clean (un-heated) copper, re-soldered the socket and applied heat shrink to the individual wires and from the sheath to the socket. The cable harness was reassembled complete with additional cable ties and with a slight increase in the size of the cable loop between the heated bed and the Y motor harness mount.

I replaced the tape on the underside of the heated bed with cloth duct tape, reassembled the controller connectors, and set about testing the heated bed. This isn’t very satisfactory as the tape peels off when the bed is hot due to the cable loom load.

Now was also a good time to clean dust out of the controller and from the cooling fans, clean and re-lubricate the linear bearings, Z axis lead screw and guides, and lubricate the belt idler bearings.

I finished the original prototype case with no bed adhesion issues. While the immediate problem has been fixed I don’t like the amount of cable flexing that occurs right at the bed during Y axis transport. Others have noted this potential issue too and have suggested attaching a cable support attached to the bed or spider. This seems like a good idea so I made a cable support rod from a 92 mm long 3 mm diameter stainless steel rod with an aluminium mounting bracket. The bracket is bolted to the edge of the heated bed by two 3 mm countersunk machine screws. The whole fixture weights just over 5 g and provides excellent cable support from the bed without any Y axis binding or drag.

Figure 3. Heated Bed Cable Support Rod

(Viewed from the bottom towards the rear of the heated bed.)

Figure 4. Heated Bed Cable Support Rod

(Viewed from the top towards the rear of the heated bed.)

If you have any questions, comments or suggestions please email me. I reply to all emails. Otherwise click here to navigate to fitting a 4 point HBP levelling system...

|