|

I’m not sure why elephants get the bad wrap for this SLA printing issue. Technically this is initial layers XY plane expansion and has nothing to do with elephants at all.

Elephant’s footing is seen as a print edge defect about 0.5 mm wider than the part for a height of about 1 mm from the build plate. It only occurs when parts are printed directly on the build plate. And it affects internal edges such as holes as well.

Figure 1. Elephant’s Footing

Figure 2. Okay, it does kinda look like an elephant’s foot

(credit New York Times)

It is caused by several factors including prolonged initial layers exposure (curing) and resin flow during the initial layer printing.

Before I prattle on it’s time for some terminology. Lifting is when the build plate travels upwards. Retraction is when it goes down. Both of these movements occur in two stages on the Saturn 2 and you can control the speed and distance of each stage. I didn’t understand this for the first month of owning my printer. The FEP is the Fluro Propylene Ethylene film atthe bottom of your resin vat. The critical stages are the initial lift which peels the model off the FEP, and the final retract to one layer height above the FEP.

Initial layer exposure time (perhaps for the first three to seven layers) is typically extended by about ten times the upper layer exposure time to ensure that the printed model is secured to the build plate. So for a typical resin with a recommended exposure time of 2.6 seconds the bottom layers will be exposed for about 26 seconds.

The reason why this prolonged exposure is necessary is a related SLA printer issue known as initial layers compression (a misnomer as the very first layer is actually too thick). So instead of being say 0.05 mm thick the very first layer is actually about 0.30 mm thick. The additional thickness takes more exposure time to cure. This issue is discussed in more detail here.

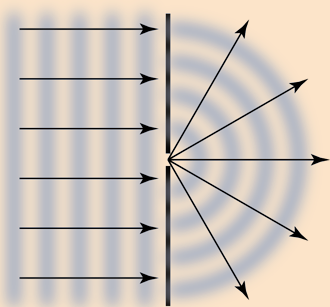

Light through a small orifice diffracts (bends) at an edge. You can blame a bloke called Huygen for this. On an SLA printer the UV light passing through a clear pixel on the LCD diffractsat the edges, causing the image to expand and blur outwards. For short exposures and small resin thickness this isn’t an issue, but for long bottom layer exposures through a relatively thick layer of resin we end up with cured or partially cured resin beyond the perimeter of our pixel.

Figure 3. Wavefront Diffraction through an Orifice

At the same time another effect is occurring. It takes time for the viscous resin to flow out between the build plate and FEP and this can be appreciable for the very first layers. So in addition to diffraction we have partially cured resin flowing away from the perimeter of the part.

The combination of these effects results in elephant’s footing. The elephant’s footing will likely be softer and lighter in colour than the part due to under-exposure.

For artistic models elephant’s foot is unlikely to be an issue. But for precision mating parts it will prevent them from engaging. For example gears won’t mesh properly, or mesh at all on design centres, and machine screws won’t fit through holes. Reworking with files, sand paper and over-drills can save a part, but this is time consuming, inexact, and will often result in an unaesthetic surface finish.

Okay, so we know the cause of elephant’s footing but how do we prevent it?

We simply need to extend the wait time between retract and cure. This reduces the thickness of the first layer of resin and reduces radial resin flow during cure. And because we now have a thinner initial layer we can reduce the bottom layer exposure time, reducing the effects of diffraction at the pixel edges.

Other folk have already figured this out. Click on eliminate elephant’s footing to do exactly that on your SLA prints.

The link will also introduce you to the excellent and free software package UV Tools. This package will give you considerable control over many aspects of your print that is not available in standard slicers such as Chitubox.

Figure 4. Elephants Saved!

(with absolutely no filing, sanding, or over-drilling.)

Click on Axial Play to link to another page on the Saturn 2.

|